7 Unique Benefits of Metal Seated Ball Valves for Global Procurement Success

In the increasingly competitive landscape of global procurement, the choice of the right components can make all the difference. One such critical component is the metal seated ball valve, renowned for its durability and reliability in high-pressure applications. According to a recent industry report, the global ball valve market is projected to reach $20 billion by 2026, with metal seated designs driving a significant portion of this growth due to their enhanced performance and extended lifespan. As industries move towards automation and more stringent regulatory standards, the adoption of metal seated ball valves has surged, offering unique advantages such as superior sealing capabilities and resistance to wear and tear. This blog will explore seven distinct benefits of metal seated ball valves, providing invaluable insights for procurement professionals aiming to optimize their operations and ensure success in a dynamic market.

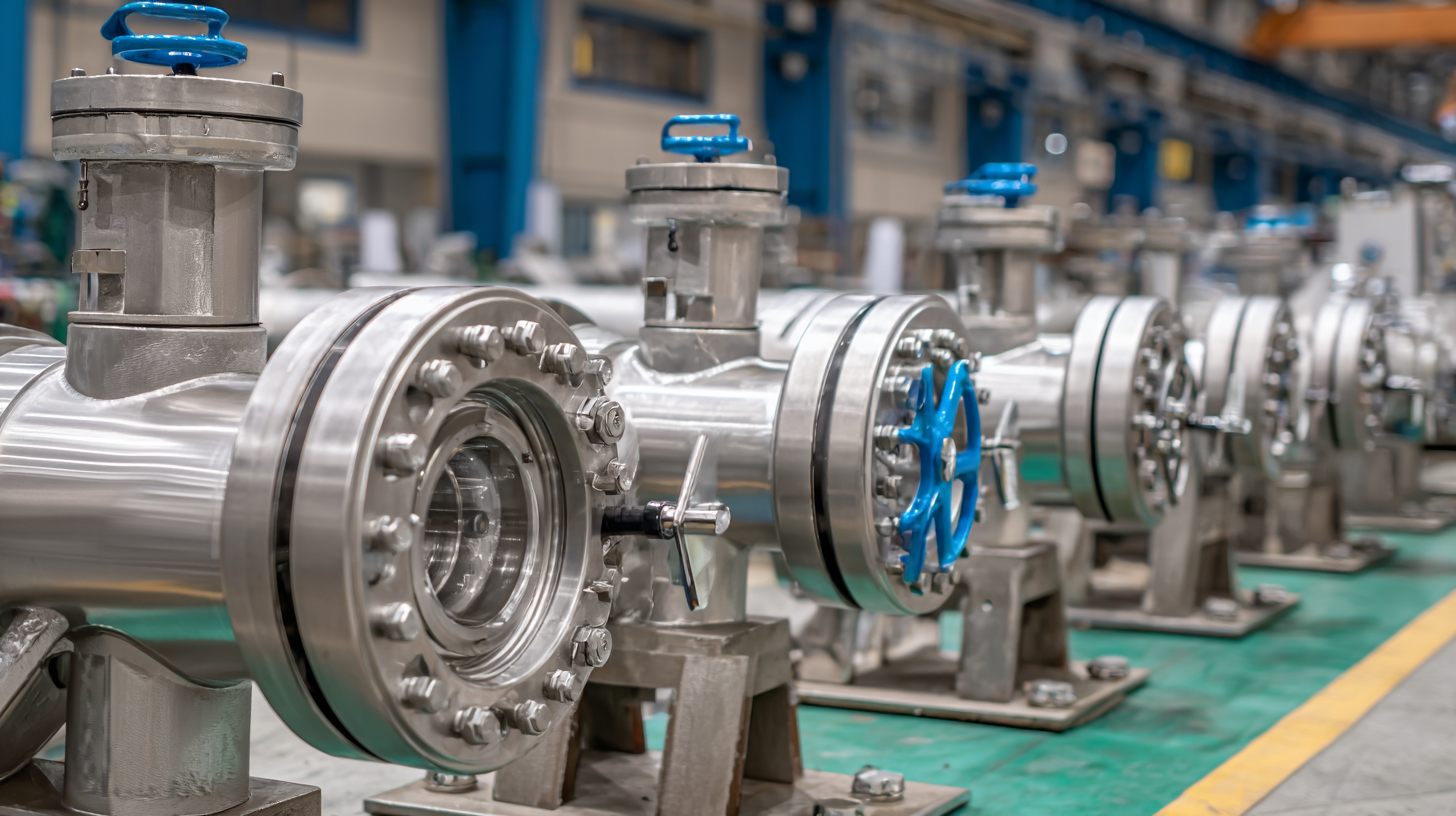

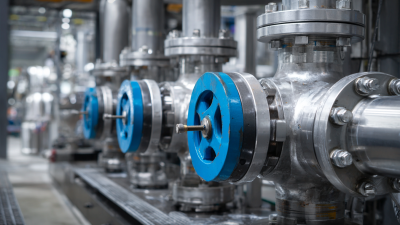

Advantages of Metal Seated Ball Valves in High-Pressure Applications

Metal seated ball valves are crucial in high-pressure applications, providing several advantages that enhance efficiency and reliability. One significant benefit is their ability to withstand high pressure and temperature extremes without compromising functionality, making them ideal for use in hydraulic systems. A recent study highlights that metallic ball seat valves with anisotropic surfaces have shown improved performance in terms of leakage management, which is critical in preventing system failures in high-stakes environments.

Metal seated ball valves are crucial in high-pressure applications, providing several advantages that enhance efficiency and reliability. One significant benefit is their ability to withstand high pressure and temperature extremes without compromising functionality, making them ideal for use in hydraulic systems. A recent study highlights that metallic ball seat valves with anisotropic surfaces have shown improved performance in terms of leakage management, which is critical in preventing system failures in high-stakes environments.

Moreover, market trends indicate a growing demand for these valves in various industries, driven by the uptick in residential construction and industrial applications. For instance, the North American market for residential ball valves is projected to see substantial growth between 2025-2035, attributed to the increased focus on safety and energy efficiency in plumbing systems. The durability and enhanced sealing capabilities of metal seated ball valves make them a preferred choice for manufacturers, ensuring that they meet the stringent requirements of high-pressure applications while maintaining operational integrity. Thus, industries can benefit significantly from adopting these specialized valves, contributing to overall procurement success on a global scale.

Cost-Effectiveness of Metal Seated Ball Valves for Global Procurement

Metal seated ball valves have become increasingly popular in global procurement due to their significant cost-effectiveness. Unlike traditional soft seated valves, metal seated variants offer enhanced durability and resilience in extreme conditions, leading to lower maintenance costs over time. Their ability to withstand higher temperatures and pressures without compromising performance ensures that they remain operational in demanding industrial applications, thereby reducing the frequency of replacements and repairs.

In addition to their long lifespan, metal seated ball valves are noted for their versatility across various sectors, including oil and gas, chemical processing, and water treatment. This adaptability means that procurement teams can streamline their purchasing process by investing in a single valve type that meets diverse operational needs. Consequently, the initial investment in metal seated ball valves can lead to substantial savings in the long run, as organizations benefit from reduced downtime and enhanced reliability. Furthermore, with a growing emphasis on sustainability, choosing these valves supports eco-friendly initiatives by minimizing waste associated with frequent replacements.

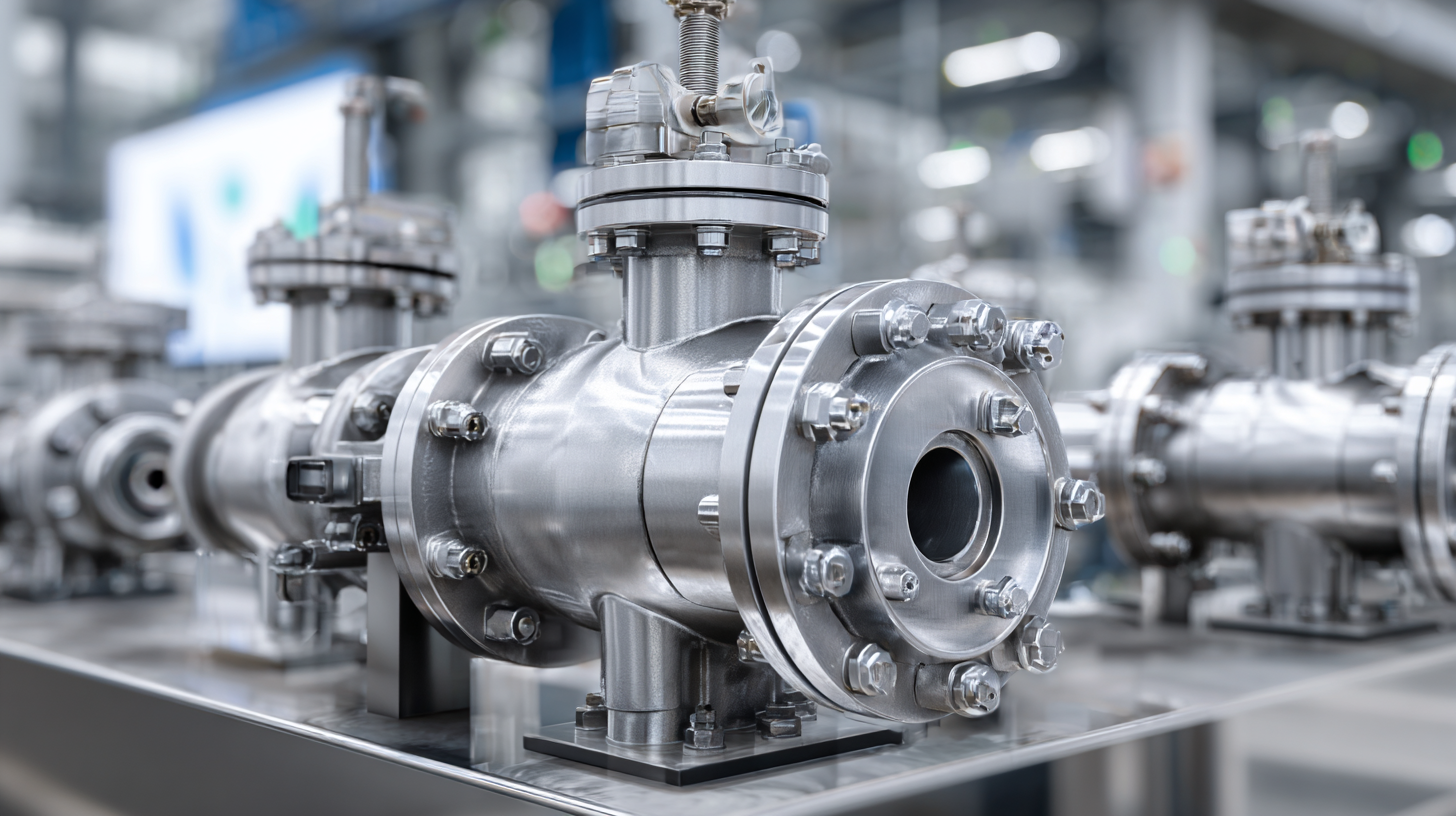

Enhanced Durability: Why Metal Seated Ball Valves Outlast Their Competitors

Metal seated ball valves demonstrate significant advantages in durability compared to traditional options, making them an essential choice for industries requiring reliable and long-lasting solutions. Recent advancements in valve technology have highlighted their enhanced resilience against wear and tear, often extending service lifetimes significantly.

For instance, reports indicate that the global industrial valve market is estimated to climb from $95.58 billion in 2024 to $121.67 billion by 2029, reflecting a growing demand for robust valve systems like metal seated ball valves.

Moreover, innovations such as wear-resistant thermal spray coatings have emerged, providing increased protection and operational lifespan for these valves. This advancement emphasizes the critical role of durability in global procurement strategies, as companies seek to optimize productivity while minimizing maintenance costs. The integration of advanced coatings not only safeguards the valves but also enhances their performance, aligning perfectly with the needs of industries focused on efficiency.

As the market continues to evolve, businesses that prioritize durable, metal seated ball valves will be well-positioned to achieve procurement success in an increasingly competitive landscape.

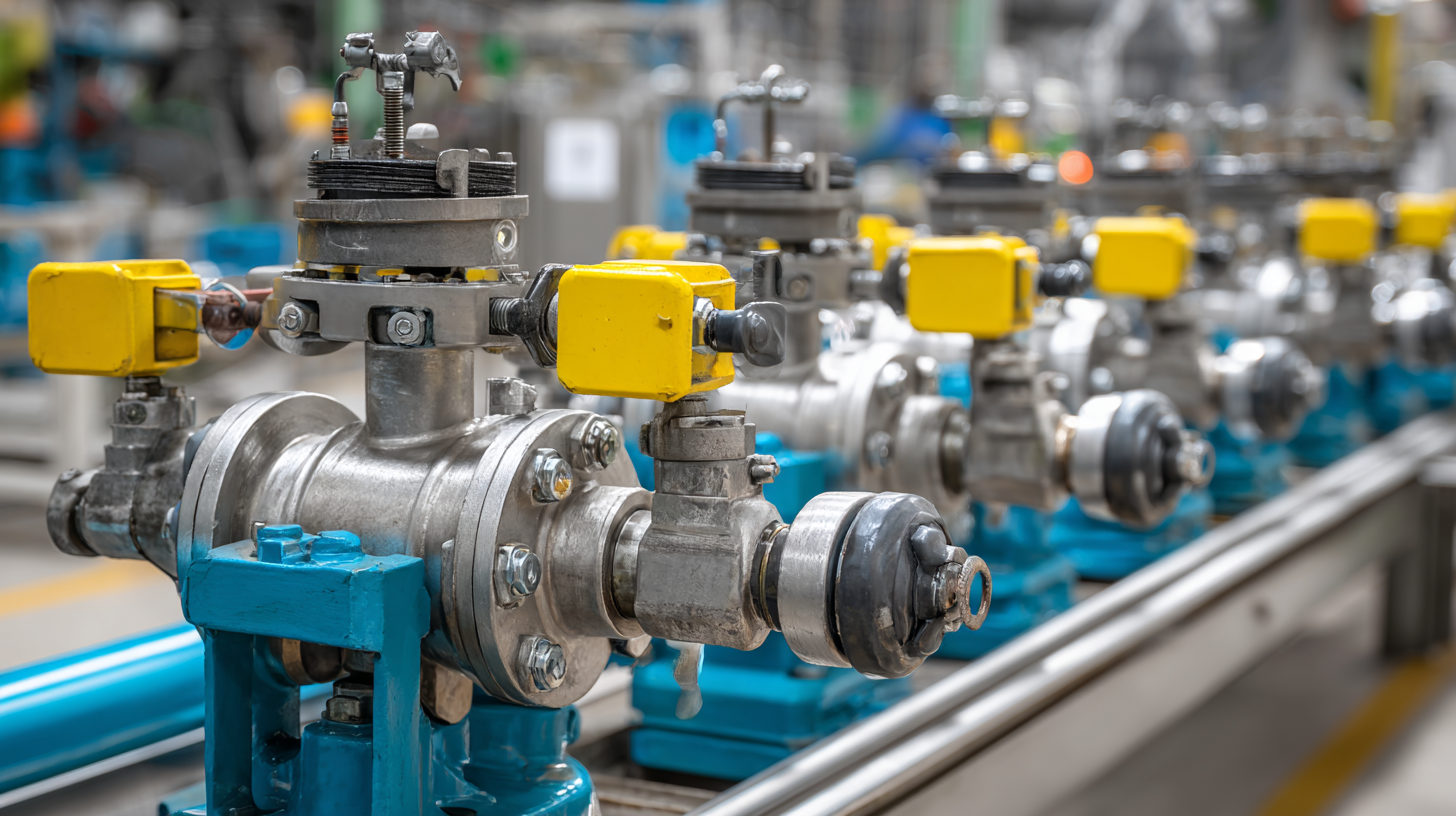

Versatility of Metal Seated Ball Valves Across Various Industries

Metal seated ball valves have gained significant traction across various industries due to their remarkable versatility and durability. These valves are designed to withstand extreme temperatures and pressures, making them ideal for critical applications in sectors like oil and gas, petrochemicals, and water treatment. Their robust construction ensures longer service life and less frequent replacements, which translates into cost savings for businesses engaging in global procurement.

When selecting metal seated ball valves, it’s essential to consider material compatibility with the fluids they will be handling. Proper material selection not only enhances the valve's performance but also reduces the risk of leakage and corrosion. Additionally, ensure the valve's design meets industry standards for efficient operation in specific environments.

Tip: Regular maintenance and inspection of metal seated ball valves can significantly extend their lifespan. Establish routine checks to monitor for wear and tear, especially in high-demand applications. This proactive approach can prevent unexpected downtime and costly repairs in your procurement process.

7 Unique Benefits of Metal Seated Ball Valves for Global Procurement Success

| Benefit | Industry Applications | Key Features | Performance Metrics |

|---|---|---|---|

| High Durability | Oil & Gas, Petrochemical | Resistant to wear and tear | Lifespan: Up to 30 years |

| Temperature Resistance | Power Generation, Chemical Processing | Able to handle extreme temperatures | Operating Range: -196°C to +600°C |

| Leakage Prevention | Water Treatment, Food Processing | Seal integrity even under high pressure | Leak Rate: < 1 x 10-6 mbar·l/s |

| Versatile Design | Manufacturing, HVAC | Various sizes and configurations available | Size Range: 1" to 48" |

| Cost Efficiency | Construction, Mining | Long-term savings on maintenance | ROI: 15% to 25% |

| Easy Maintenance | Aerospace, Pharmaceutical | Reduced downtime for servicing | Service Intervals: Every 2-5 years |

| Environmentally Friendly | Waste Management, Renewable Energy | Supports sustainable practices | Recyclable materials |

Improved Performance and Reduced Maintenance with Metal Seated Ball Valves

Metal seated ball valves are revolutionizing industrial applications by offering enhanced performance and significantly reducing maintenance costs. Unlike traditional soft-seated valves, metal seated options are designed to withstand extreme conditions, such as high temperatures and corrosive substances, making them a reliable choice for global procurement strategies. Their durability ensures that systems operate efficiently with minimal downtime, a critical factor in maintaining productivity.

To maximize the advantages of metal seated ball valves, it is essential to consider proper application compatibility. Always assess the operating conditions, including pressure and temperature, to ensure the selected valve meets the necessary specifications. Additionally, regular inspections and proactive maintenance can extend the lifespan of these valves, further reducing long-term costs.

Another tip is to keep an eye on the flow characteristics within your system. Metal seated valves offer tight shut-off capabilities, but ensuring that they are not oversized can help prevent flow turbulence and potential system inefficiencies. Understanding your operational needs will guide you in choosing the right size and type, ensuring seamless integration into your procurement process.

Related Posts

-

5 Reasons Why the Best 3 Flanged Ball Valves Revolutionize Industrial Efficiency

-

Solutions for Sourcing the Best Ball Valve Balls: A Global Procurement Guide

-

Ultimate Checklist for Selecting the Best Valve Ball Valve for Your Industrial Needs

-

Solutions for Choosing the Best Steel Ball Valves: Key Insights from Industry Trends and Data

-

Understanding the Significance of the Best High Pressure Ball Valve in Industrial Applications

-

Understanding the Functionality of Ball Valve Balls in Modern Industrial Applications