Comparing Three Way Valve Designs for Optimal Efficiency in Global Supply Chains

In the complex landscape of global supply chains, optimizing efficiency is paramount, and one critical component that often goes overlooked is the three way valve. This device plays a pivotal role in fluid and gas control systems, influencing not only the performance of machinery but also the overall flow of materials within a supply chain. As industries strive to enhance operational efficiency, the choice of valve design can significantly affect both performance and costs. In this blog, we will compare three distinct designs of three way valves, examining their functionalities, advantages, and applications. By understanding the nuances of each design, businesses can make informed decisions that lead to improved performance, reduced downtime, and ultimately, a more streamlined supply chain. Join us as we delve into the world of three way valves and explore how the right choice can drive optimal efficiency in your operations.

Understanding the Functionality of Three Way Valves in Supply Chains

The COVID-19 pandemic has highlighted the critical importance of efficient supply chains in healthcare, particularly when lives are at stake. An Italian hospital's innovative use of 3D printing to produce valves for reanimation devices exemplifies how technology can restore functionality in supply chains disrupted by crisis. This application not only addresses immediate healthcare needs but also underscores the broader theme of resilience in global value chains. Businesses increasingly recognize the necessity of understanding their vulnerabilities and strategizing accordingly to mitigate risks, ensuring that they can respond swiftly to unforeseen challenges.

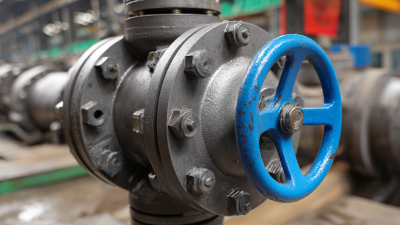

In the context of supply chain efficiency, the functionality of three-way valves plays a significant role in managing fluid dynamics within various systems. These valves are essential for directing flow and meeting operational demands in parallel-connected systems. Their ability to optimize flow allows enterprises to enhance performance while minimizing waste and inefficiencies. As industries grapple with supply chain disruptions, understanding how these components operate can guide the development of more resilient infrastructures that adapt to changing circumstances, ultimately fostering innovation in supply chain management.

Comparing Efficiency of Three Way Valve Designs in Supply Chains

This chart compares the efficiency of different three way valve designs in global supply chains, highlighting flow rates for high, medium, and low efficiency options.

Evaluating Different Three Way Valve Designs for Efficiency

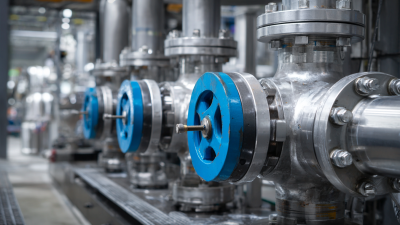

In the realm of global supply chains, the efficiency of fluid handling systems is paramount, and three-way valves play a crucial role in this equation. Different designs of three-way valves can significantly impact the flow dynamics, response times, and overall operational efficiency of supply chain processes. By evaluating various configurations such as L-port and T-port designs, industries can determine which options best facilitate the required fluid control in their unique applications.

L-port valves, for example, are ideal for simple diverting applications, allowing for straightforward switching between two necessary flow paths. In contrast, T-port valves can handle more complex tasks, enabling mixing and diverting of flows simultaneously. Understanding the specific requirements of each application is essential, as factors like pressure, temperature, and fluid type can influence the performance of different valve designs. By conducting thorough evaluations of these three-way valve options, businesses can make informed decisions that enhance efficiency in their operations and ultimately position them for competitive advantage in the global marketplace.

Key Factors Influencing the Performance of Three Way Valves

In the complex landscape of global supply chains, the efficiency of fluid control systems is paramount. Three way valves play a critical role in optimizing the flow of materials, ensuring smooth operations across various sectors. Industry reports indicate that approximately 30% of fluid handling costs can be attributed to valve inefficiencies, highlighting the need for careful selection and design of these components. Factors such as flow rate, pressure drop, and valve type significantly influence overall performance, necessitating a thorough understanding of each variation.

Tips: When selecting a three way valve, consider the application requirements and operating environment. Evaluate parameters like flow capacity and compatibility with the system fluid. Monitoring pressure drops can also lead to significant cost savings—research shows that minimizing pressure drops by just 1 psi can save up to 5% on energy costs in fluid transport operations.

Additionally, the material choice for the valve body is crucial. According to industry analysts, up to 15% of maintenance costs arise from corrosion-related failures in valves. Selecting a corrosion-resistant material can enhance longevity and reduce downtime, thereby improving supply chain efficiency. By focusing on these key factors, companies can maximize their investment in three way valve technology and stay ahead in the competitive market.

Comparing Three Way Valve Designs for Optimal Efficiency in Global Supply Chains - Key Factors Influencing the Performance of Three Way Valves

| Valve Design | Material | Flow Rate (m³/h) | Pressure Drop (bar) | Temperature Range (°C) | Maintenance Frequency (months) |

|---|---|---|---|---|---|

| Design A | Stainless Steel | 50 | 1.2 | -20 to 200 | 6 |

| Design B | Brass | 75 | 0.8 | -10 to 160 | 12 |

| Design C | PVC | 30 | 1.5 | 0 to 60 | 24 |

Best Practices for Implementing Three Way Valves in Logistics

Implementing three-way valves in logistics requires careful consideration to enhance efficiency and optimize supply chain processes. One best practice is to conduct a thorough assessment of the specific requirements of your system before choosing a valve design. Understanding the flow dynamics and pressure conditions can help in selecting a valve that balances durability and performance.

Tips: When assessing your needs, engage engineers and stakeholders to evaluate existing systems. Consider factors such as compatibility with current infrastructure and potential for future scalability.

Another best practice involves regular maintenance and monitoring of the valves in operation. Integrating an automated monitoring system can provide real-time data on valve performance, allowing for timely interventions and reducing the risk of downtime.

Tips: Implement predictive maintenance schedules based on usage data, and train staff on recognizing early signs of valve failure. This proactive approach not only extends the lifespan of the valves but also enhances overall operational efficiency.

Future Trends in Three Way Valve Technologies for Supply Chain Optimization

As global supply chains become increasingly complex, the efficiency of fluid control systems, particularly three way valves, is paramount. According to a recent market analysis by Markets and Markets, the global valve market is projected to reach $106.43 billion by 2026, driven largely by advancements in automation and control technologies. This growth highlights the critical role that three way valves play in optimizing processes, ensuring precise fluid flow management across diverse applications.

Future trends in three way valve technologies focus on incorporating smart features, such as IoT connectivity and real-time monitoring capabilities. A report from Grand View Research reveals that the smart valve market is expected to grow at a CAGR of 23.1% from 2021 to 2028. This integration allows for enhanced predictive maintenance, reducing downtime and associated costs. As industries strive for sustainability, the development of energy-efficient valve designs that reduce leakage and optimize flow rates will also become essential. By embracing these innovations, companies can significantly improve their operational efficiency while adapting to the evolving demands of global supply chains.

Related Posts

-

China's Leading Factory Delivers Outstanding Best 3 Way Ball Valves to Global Buyers

-

Solutions for Sourcing the Best Ball Valve Balls: A Global Procurement Guide

-

Understanding the Significance of the Best High Pressure Ball Valve in Industrial Applications

-

5 Reasons Why the Best 3 Flanged Ball Valves Revolutionize Industrial Efficiency

-

Global Leaders Choice for Best Three Way Ball Valves Quality Manufacturing from China

-

Ultimate Checklist for Selecting the Best Valve Ball Valve for Your Industrial Needs