How to Select the Right Flanged Ball Valve for Optimal Performance in Your Industry Applications

In today's rapidly evolving industrial landscape, selecting the right components for fluid management is critical for ensuring optimal performance and reliability. One key component that often plays a vital role in various applications is the flanged ball valve. These valves not only provide excellent sealing capabilities but also offer ease of maintenance and enhanced flow control, making them an indispensable choice for many industries. However, with a myriad of options available in the market, understanding how to choose the best flanged ball valve tailored to your specific needs can be a daunting task. This blog will guide you through essential considerations and best practices for selecting the right flanged ball valve, ensuring you make an informed decision that enhances operational efficiency and meets the rigorous demands of your industry applications.

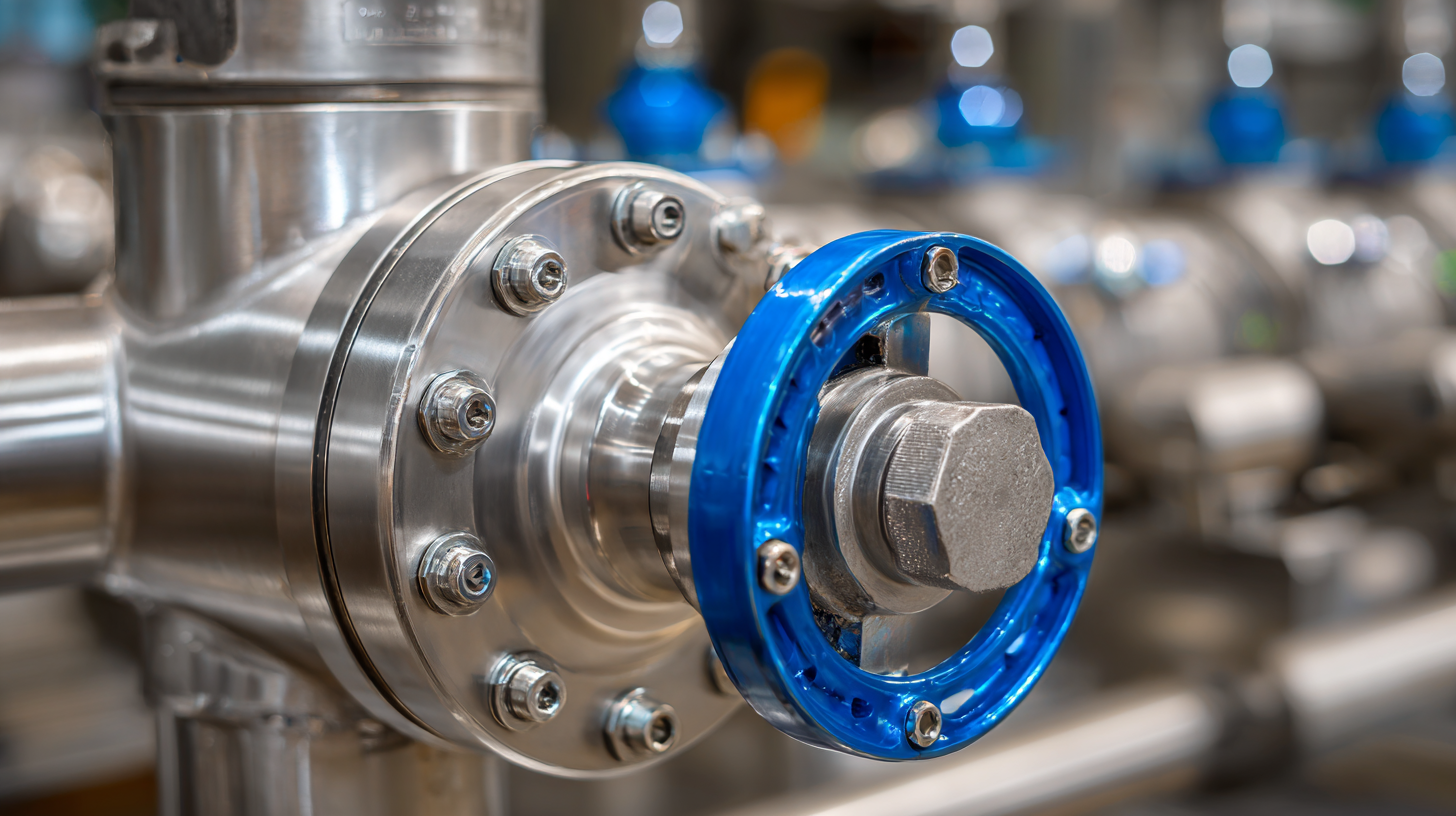

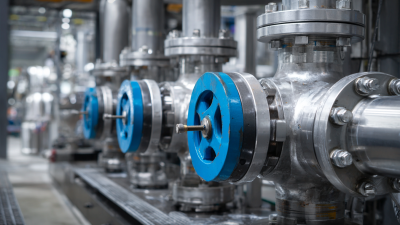

Understanding the Basics: What is a Flanged Ball Valve and Its Applications

Flanged ball valves are essential components in various industrial applications, offering reliable flow control and efficient performance. These valves feature a robust design with flanged connections, allowing for easier installation and maintenance. Understanding the basics of flanged ball valves is crucial for industries aiming to optimize their processes. Typically utilized in systems where quick shut-off is required, flanged ball valves can handle a wide range of pressures and temperatures, making them suitable for everything from water and gas supply to chemical processing.

When selecting the right flanged ball valve, several factors must be considered, including the specific requirements of your application. High-pressure environments, for example, call for valves that not only meet operational demands but also adhere to established standards for safety and performance. Recent advancements in valve technology, such as new gearboxes and innovative designs, offer enhanced features that further improve efficiency. It’s also vital to consider compatibility with existing systems and adherence to industry standards, ensuring that your chosen valve performs optimally and contributes to the overall reliability of your operations.

Key Factors to Consider When Selecting a Flanged Ball Valve for Your Industry

When selecting a flanged ball valve for optimal performance in your industry applications, there are several key factors to consider. First and foremost, understanding the operational environment is crucial. Factors such as temperature, pressure, and the type of fluid being handled can significantly influence the valve's performance. For instance, in high-pressure environments, the material and design of the valve must be able to withstand the added stress, ensuring safety and reliability.

Another essential consideration is the valve's construction. Materials should be chosen based on their resistance to corrosion and wear, particularly in harsh applications such as oil and gas or wastewater management. Additionally, the valve's compatibility with existing pipeline systems and ease of installation can also play a pivotal role in the selection process. Recent advancements in valve technology, such as innovations in cryogenic ball valves, provide solutions designed to minimize issues like fugitive emissions, making it vital to stay informed on new products that enhance operational efficiency.

Flanged Ball Valve Selection Factors

This chart represents key factors to consider when selecting a flanged ball valve for various industry applications, including Pressure Rating, Size, Material, and Temperature Ratings.

Material Compatibility: Choosing the Right Valve for Your Fluid Type

When selecting a flanged ball valve, material compatibility is crucial for ensuring optimal performance in various industrial applications. Different fluids, whether they are corrosive chemicals, high-temperature steam, or standard water, require specific valve materials to prevent degradation and ensure longevity. According to a report by the Valve Manufacturers Association, improper material selection can lead to significant operational costs, with some industries experiencing up to a 30% decrease in efficiency due to valve failures attributed to material incompatibility.

For instance, using stainless steel valves in applications involving hydrochloric acid is a common mistake, as the acid can severely corrode the metal. Instead, valves made from corrosion-resistant alloys like Hastelloy might be more suitable for such fluids. The American Society of Mechanical Engineers (ASME) recommends considering material factors such as corrosion potential, temperature, and pressure conditions before making a selection. By following these guidelines and utilizing compatible materials, industries can enhance their operational efficiency and reduce downtime, ultimately leading to a significant impact on their bottom line.

Sizing and Pressure Ratings: Ensuring Optimal Performance in Your System

When selecting a flanged ball valve for your industry applications, understanding sizing and pressure ratings is essential for ensuring optimal performance. The size of the valve should match the pipe diameter in your system to maintain fluid flow efficiency. An oversize valve can lead to increased pressure loss, while an undersize valve may risk it becoming a bottleneck, leading to operational issues.

Tips: Always consult the manufacturer's sizing charts and consider factors such as the flow rate and the type of medium being transported. Accurate sizing ensures your valve performs within the desired parameters, enhancing reliability and longevity.

Pressure ratings are equally crucial. Ensure that the valve's pressure rating exceeds the maximum pressure experienced in your system. This not only prevents potential leaks and failures but also enhances the safety of the operation.

Tips: Verify the pressure class and the material compatibility with your specific application; this step can mitigate risks associated with pressure surges and chemical corrosion, ultimately leading to a more efficient and safe operation.

Maintenance and Lifecycle: Best Practices for Long-lasting Flanged Ball Valves

When it comes to ensuring optimal performance of flanged ball valves, understanding maintenance and lifecycle best practices is essential. Regular inspection and maintenance can significantly extend the lifespan of these valves, which are critical in various industry applications. According to a report by the American Society of Mechanical Engineers (ASME), properly maintained valves can outlast their unmaintained counterparts by up to 50%. This highlights the importance of integrating proactive maintenance strategies into operational protocols.

Maintenance best practices include routine visual inspections, periodic testing for leaks, and lubrication of moving components to prevent corrosion and wear. The Valve Manufacturers Association (VMA) suggests that performing maintenance at least once a year can help identify potential issues before they lead to failure. Moreover, utilizing condition monitoring technologies, such as vibration analysis and ultrasonic testing, can help predict maintenance needs, thereby reducing unexpected downtime. By adhering to these practices, industries can ensure that their flanged ball valves operate efficiently, thereby optimizing the overall performance and reliability of their systems.

How to Select the Right Flanged Ball Valve for Optimal Performance in Your Industry Applications - Maintenance and Lifecycle: Best Practices for Long-lasting Flanged Ball Valves

| Attribute | Details |

|---|---|

| Valve Type | Flanged Ball Valve |

| Common Materials | Stainless Steel, Carbon Steel, PVC |

| Pressure Rating | 150 psi to 3000 psi |

| Temperature Range | -50°F to 500°F |

| Applications | Chemical, Oil & Gas, Water Treatment |

| Maintenance Frequency | Every 6 to 12 months |

| Lifecycle Duration | 10 to 25 years |

| Best Practice | Regular Inspections and Cleaning |

Related Posts

-

Advantages of 3 Flanged Ball Valves for Efficient Fluid Control Solutions

-

5 Reasons Why the Best 3 Flanged Ball Valves Revolutionize Industrial Efficiency

-

How to Select the Right 3 Flanged Ball Valve for Your Industrial Needs: A Comprehensive Guide

-

Understanding the Significance of the Best High Pressure Ball Valve in Industrial Applications

-

Understanding the Functionality of Ball Valve Balls in Modern Industrial Applications

-

Solutions for Choosing the Best Steel Ball Valves: Key Insights from Industry Trends and Data