How to Select the Right 3 Flanged Ball Valve for Your Industrial Needs: A Comprehensive Guide

In the industrial sector, the selection of the right valve is crucial for ensuring operational efficiency and safety. Among the various types of valves available, the 3 flanged ball valve has emerged as a popular choice due to its reliability and versatility in handling different fluids. According to a report by Markets and Markets, the global industrial valves market is expected to reach $110 billion by 2025, with a significant share attributed to ball valves. Their ability to facilitate quick shut-off and maintain tight seals under high pressure makes them essential in various applications, including oil and gas, water treatment, and chemical processing. However, with the myriad of options available, selecting the right 3 flanged ball valve tailored to specific industrial needs can be daunting. This comprehensive guide aims to simplify the decision-making process, providing essential tips and insights to help you choose the most suitable valve for your operations.

Understanding the Basics of Flanged Ball Valves for Industrial Applications

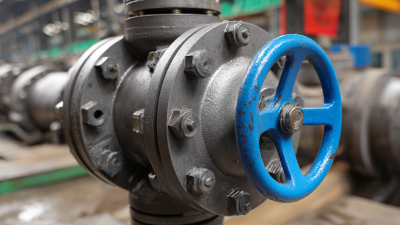

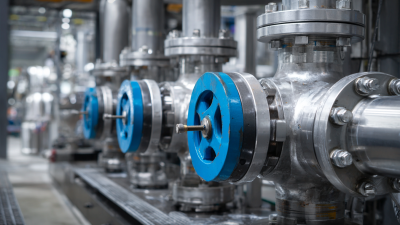

Flanged ball valves are essential components in various industrial applications, providing reliable flow control and sealing capabilities. Understanding the basics of these valves is critical for selecting the right one for your specific needs.

A flanged ball valve features a spherical disc that controls flow, and its flanged connections ensure a secure, leak-proof assembly with pipelines. The design allows for easy installation and maintenance, making it a preferred choice in many industries.

A flanged ball valve features a spherical disc that controls flow, and its flanged connections ensure a secure, leak-proof assembly with pipelines. The design allows for easy installation and maintenance, making it a preferred choice in many industries.

When selecting a flanged ball valve, consider the material compatibility with your fluid. Different materials, such as stainless steel, brass, or plastic, offer varying degrees of resistance to corrosion and pressure. Additionally, be aware of the valve's pressure rating and temperature limits to ensure it can withstand your operational conditions effectively.

Another important tip is to assess the valve's actuator options. Manual or automated actuators can significantly impact operational efficiency. If your process requires remote control or frequent adjustments, opting for a valve with an electric or pneumatic actuator may enhance productivity. Always consider the specific requirements of your application to ensure optimal valve performance.

Key Factors to Consider When Selecting Flanged Ball Valves

When selecting flanged ball valves for industrial applications, several key factors must be taken into consideration to ensure optimal performance and reliability. First, the material of the valve is crucial. Depending on the application, it might be necessary to choose between stainless steel, carbon steel, or plastic materials. Each option has its unique advantages and is suitable for specific conditions, such as high pressure, temperature extremes, or corrosive environments. Understanding the media being controlled is essential in making this decision.

Another important factor is the valve size and pressure rating, which should match the piping system's specifications. Proper sizing ensures that the valve can handle the required flow rate without causing pressure drops that could affect system efficiency. Additionally, it’s essential to consider the type of flanges used in the installation. Standards such as ANSI, DIN, or JIS may apply, and compatibility with existing piping will influence your selection. Lastly, the actuation method, whether manual or automated, should be evaluated to accommodate operational requirements and maintenance capabilities. By addressing these criteria, you can confidently choose the right flanged ball valve for your industrial needs.

How to Select the Right 3 Flanged Ball Valve for Your Industrial Needs: A Comprehensive Guide

| Key Factor | Description | Importance Level |

|---|---|---|

| Material Type | Choose based on the media being handled (e.g., water, oil, chemicals). | High |

| Valve Size | Ensure the valve size matches the pipe size for optimal flow. | Medium |

| Pressure Rating | Select a valve that can handle the operating pressure of your system. | High |

| Temperature Range | Make sure the valve can operate within the intended temperature limits. | Medium |

| End Connections | Choose the right type of flanges that match your piping system. | Medium |

| Actuation Type | Consider manual vs. automatic actuation based on your needs. | Low |

Top 3 Material Types for Flanged Ball Valves and Their Uses

When selecting a flanged ball valve for industrial applications, the choice of material is crucial to ensure durability, performance, and compatibility with the fluid being handled. The top three material types used for flanged ball valves are stainless steel, carbon steel, and plastic, each offering unique benefits suited to different environments.

Stainless steel is renowned for its corrosion resistance and strength, making it ideal for applications involving chemicals or high temperatures. Its versatility allows it to be used in a wide range of industries, from food processing to pharmaceuticals. On the other hand, carbon steel provides excellent durability and is often more economical for projects that do not involve corrosive substances. It is commonly used in the oil and gas industry, where robustness is paramount.

Lastly, plastic flanged ball valves are lightweight, resistant to corrosion, and suitable for less demanding applications such as water treatment and HVAC systems. Their ease of installation and handling makes them a favorable choice in specific operational contexts, particularly where chemical resistance is a requirement.

By understanding the distinctions and applications of these material types, professionals can make informed decisions to optimize their industrial processes and enhance valve longevity.

5 Common Mistakes to Avoid When Choosing a Flanged Ball Valve

When selecting a flanged ball valve for your industrial applications, avoiding common pitfalls is essential to ensure efficiency and longevity. One major mistake is overlooking the valve's pressure rating. It’s critical to choose a valve that can withstand your system’s operating conditions. Failing to do so can lead to premature failure or catastrophic leaks. Always check the specifications and ensure the valve can handle the maximum pressure and temperature of your application.

Another common mistake is not considering the material compatibility. Different applications require different materials based on the media being transported. For instance, using a valve with carbon steel in a corrosive environment may lead to rapid degradation. Always verify that the valve's material aligns with the chemical properties of the substances it will handle.

A final tip is to neglect maintenance needs. Some flanged ball valves require more frequent maintenance than others. Opting for a valve that is easy to service can save both time and costs in the long run. Ensure you review the manufacturer's guidelines and choose a valve that fits not only your operational needs but also your maintenance capabilities.

Expert Tips for Ensuring Optimal Performance of Flanged Ball Valves

When selecting the right 3 flanged ball valve for industrial applications, ensuring optimal performance hinges on several key factors. According to a recent report by the Market Research Future, the global ball valve market is expected to reach $16.2 billion by 2027, emphasizing the growing importance of choosing high-quality components. Understanding your system’s pressure and temperature specifications is crucial in this selection process.

Tip 1: Always consider the materials used in the valve construction as they must withstand the conditions specific to your application. For instance, valves made from alloys like stainless steel are preferred in corrosive environments, providing longevity and reducing maintenance costs.

Tip 2: Pay special attention to the valve size and flow characteristics. A well-sized flanged ball valve can significantly decrease energy loss and improve system efficiency. According to the International Society of Automation, properly sized valves can enhance flow accuracy by up to 20%, leading to a more efficient operation.

Adopting these expert tips will not only ensure that you select the right valve but also help enhance the overall reliability and effectiveness of your industrial systems.

Related Posts

-

5 Reasons Why the Best 3 Flanged Ball Valves Revolutionize Industrial Efficiency

-

China's Leading Factory Delivers Outstanding Best 3 Way Ball Valves to Global Buyers

-

Solutions for Sourcing the Best Ball Valve Balls: A Global Procurement Guide

-

Ultimate Checklist for Selecting the Best Valve Ball Valve for Your Industrial Needs

-

Understanding the Significance of the Best High Pressure Ball Valve in Industrial Applications

-

Understanding the Functionality of Ball Valve Balls in Modern Industrial Applications