Understanding the Functionality of Ball Valve Balls in Modern Industrial Applications

In the realm of modern industrial applications, the significance of the ball valve ball cannot be overstated. As a critical component in various fluid control systems, the ball valve ball serves not only as a mechanical device that regulates the flow of liquids and gases but also enhances operational efficiency and safety. This introduction explores the myriad benefits of utilizing ball valve balls in industrial settings, highlighting their robust design, versatility, and reliability. By understanding the functionality of these vital components, industries can optimize performance, reduce maintenance costs, and ensure seamless operation across a range of applications, from oil and gas to water treatment. As we delve deeper into the advantages of ball valve balls, we will uncover how they contribute to the overall effectiveness and sustainability of modern industrial systems.

The Evolution of Ball Valves: A Historical Perspective

Ball valves have undergone significant evolution since their inception, becoming a vital component in modern industrial applications. Initially, the concept of a rotating ball to control flow dates back to the 1950s, when they were primarily used in groundwater and irrigation systems. The innovative design allowed for a more efficient flow control compared to traditional valves, such as gate or globe valves. Over the decades, as industrial processes became more complex, the need for reliable and durable flow control mechanisms propelled the development of ball valves.

As technology advanced, so did the materials and designs of ball valves. The introduction of new materials like stainless steel and plastics improved durability and chemical resistance, allowing ball valves to be used in a wider range of applications, from oil and gas to pharmaceuticals. Automation also played a pivotal role in the evolution of ball valves, leading to the creation of electric and pneumatic actuators. This integration of technology not only enhanced precision and control but also enabled the development of smart valve solutions capable of real-time monitoring and control in demanding industrial environments. Today, ball valves stand as an example of how innovation has transformed industrial valve design, meeting the needs of increasingly sophisticated applications.

Understanding Ball Valve Usage Over the Years

This bar chart illustrates the growing adoption of ball valves in various industrial applications from the 1960s to the 2020s. The increasing percentage indicates the evolution and importance of ball valves in modern industrial systems.

Key Materials Used in Ball Valve Fabrication for Enhanced Durability

In modern industrial applications, the durability and performance of ball valves heavily depend on the materials used in their fabrication. Key materials such as stainless steel, carbon steel, and special alloys have gained prominence due to their resistance to corrosion, temperature variations, and pressure fluctuations. According to a 2022 report by the International Society of Automation, stainless steel constitutes approximately 70% of the ball valve market, primarily owing to its excellent mechanical properties and longevity, which significantly reduce maintenance costs in industrial operations.

Moreover, advancements in polymer materials have led to the development of innovative ball valve designs that offer enhanced durability. For instance, reinforced PTFE (Polytetrafluoroethylene) is increasingly being used for its superior chemical resistance and low friction properties. A study published by the Journal of Materials Engineering in 2023 highlighted that ball valves incorporating this material exhibit a life expectancy increase of up to 40% compared to traditional designs. As industries opt for more sustainable and efficient solutions, the selection of materials for ball valve fabrication remains a critical factor in ensuring reliable performance under demanding conditions.

How Ball Valve Balls Function: Mechanisms and Applications Explored

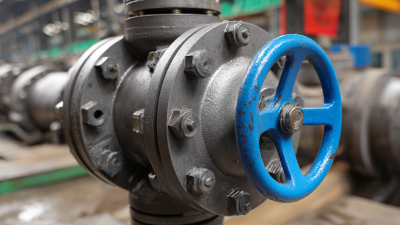

Ball valve balls are crucial components in modern industrial applications, acting as the primary mechanism for controlling fluid flow. Their spherical design allows for efficient sealing, minimizing leakage and ensuring reliable operation under various pressure and temperature conditions. Understanding the underlying mechanisms by which these ball valves operate can greatly enhance their application in industries ranging from oil and gas to pharmaceuticals.

One core mechanism of ball valve functionality is the precise alignment of the ball within the valve body. This alignment ensures that when the valve is closed, the ball fits snugly against the seat, preventing fluid passage. Additionally, the material composition of the ball influences its performance; for instance, using corrosion-resistant alloys can extend the valve's lifespan in harsh environments.

**Tips:** When selecting ball valves for industrial applications, consider factors such as the operational pressure, temperature, and the chemical properties of the fluids involved. Regular maintenance checks can also help identify wear and tear early, ensuring long-term efficiency. Moreover, integrating advanced technologies like piezoelectric energy harvesters can optimize valve performance by harnessing ambient energy for enhanced controls and monitoring.

Comparative Advantages of Ball Valves Over Other Valve Types in Industry

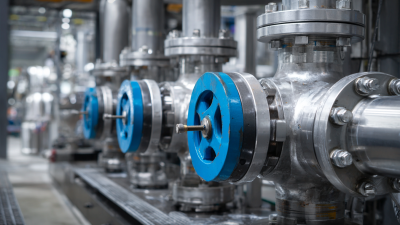

Ball valves have emerged as a preferred choice in various industrial applications due to their superior functionality and efficiency when compared to other valve types. According to a report from TechSci Research, the global ball valve market is projected to reach $10.3 billion by 2026, demonstrating a compound annual growth rate (CAGR) of 5.6% between 2021 and 2026. This growth is largely attributed to the advantages that ball valves offer, including their high flow capacity and low pressure drop, making them ideal for controlling the flow of liquids and gases.

One of the key comparative advantages of ball valves is their ability to provide a reliable seal, even under high temperatures and pressures. The design of the ball valve minimizes the risk of leaks, which is crucial in industries such as oil and gas, where safety is a paramount concern. Moreover, ball valves allow for quick opening and closing, typically requiring only a quarter turn to move from the fully open to fully closed position. This rapid operation can significantly enhance system performance and reduce downtime. In addition, the durability of materials used in ball valve manufacturing contributes to lower maintenance costs, further solidifying their standing as an industrial staple.

Understanding the Functionality of Ball Valve Balls in Modern Industrial Applications - Comparative Advantages of Ball Valves Over Other Valve Types in Industry

| Valve Type | Flow Efficiency (%) | Pressure Drop (Psi) | Operational Life (Years) | Maintenance Frequency (Years) | Cost of Maintenance ($) |

|---|---|---|---|---|---|

| Ball Valve | 95 | 5 | 20 | 5 | 500 |

| Gate Valve | 80 | 10 | 15 | 10 | 400 |

| Globe Valve | 70 | 15 | 10 | 7 | 600 |

| Check Valve | 85 | 8 | 12 | 8 | 450 |

Future Trends: Innovations Shaping the Next Generation of Ball Valves

In recent years, the industrial sector has witnessed significant advancements in the design and technology of ball valves, leading to innovative trends that promise to redefine their functionality and efficiency. One prominent trend is the integration of smart technology, where ball valves are equipped with sensors and IoT capabilities. This allows for real-time monitoring and data collection, enabling predictive maintenance and reducing downtime in critical operations. Industries can now harness the power of data analytics to optimize valve performance and improve overall system reliability.

Another noteworthy innovation is the development of advanced materials used in ball valve construction. Manufacturers are exploring lightweight composites and corrosion-resistant alloys, which enhance durability and reduce wear in harsh environments. Additionally, advancements in manufacturing processes, such as 3D printing, are allowing for more complex designs and rapid prototyping. This flexibility not only accelerates the production cycle but also enables the creation of custom solutions tailored to specific industrial needs.

As industries continue to prioritize efficiency and sustainability, the next generation of ball valves is set to play a pivotal role in meeting these evolving demands.

Related Posts

-

Ultimate Checklist for Selecting the Best Valve Ball Valve for Your Industrial Needs

-

Solutions for Sourcing the Best Ball Valve Balls: A Global Procurement Guide

-

Understanding the Significance of the Best High Pressure Ball Valve in Industrial Applications

-

5 Reasons Why the Best 3 Flanged Ball Valves Revolutionize Industrial Efficiency

-

Solutions for Choosing the Best Steel Ball Valves: Key Insights from Industry Trends and Data

-

China's Leading Factory Delivers Outstanding Best 3 Way Ball Valves to Global Buyers