How to Effectively Choose the Right Three Way Valve for Your Industrial Needs

In the world of industrial processes, selecting the appropriate three way valve can significantly impact efficiency and operational costs. According to a recent market research report by MarketsandMarkets, the global valve market is projected to reach $103.2 billion by 2025, with three way valves accounting for a substantial portion due to their versatility in controlling flow direction. As industries such as oil and gas, water treatment, and chemical manufacturing increasingly adopt automation and advanced control technologies, the demand for reliable and efficient valves continues to rise. A well-chosen three way valve not only enhances system performance but also contributes to improving safety and productivity. This blog aims to guide you through the essential considerations for selecting the right three way valve tailored to your specific industrial needs.

Understanding the Key Functions and Types of Three Way Valves

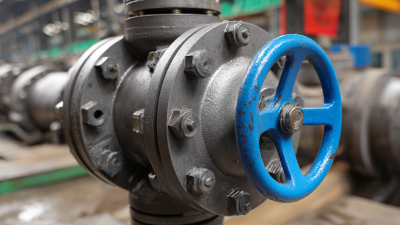

When selecting a three way valve for industrial applications, understanding its key functions is crucial. Three way valves are generally used to control the flow of fluids by diverting or mixing them. They feature three ports: one inlet and two outlets or vice versa, allowing for flexibility in system design.

Common types include L-port and T-port configurations, each serving distinct roles. L-port valves are ideal for diverting flows, while T-port valves can mix flows or split them between two outlets.

Tip: Always consider the specific requirements of your application, such as temperature and pressure ratings, to find the right valve that ensures optimal performance.

Another critical factor is the actuation method. Valves can be operated manually, electrically, or pneumatically, depending on your operational needs. Electric options may offer precision control, while pneumatic ones provide quicker response times. The choice of actuation method should align with the overall automation strategy of your facility.

Tip: Focus on the ease of maintenance and access to the valve itself, as this can significantly reduce downtime and facilitate a seamless operational flow.

Factors to Consider When Selecting a Three Way Valve for Your Application

When selecting a three-way valve for your industrial application, several key factors must be taken into account to ensure optimal performance and efficiency. First, understanding the flow requirements is essential. Three-way valves are commonly used for diverting or mixing flows; thus, knowledge of the desired flow direction and capacity is critical. According to industry reports, a well-chosen valve can improve system efficiency by up to 20%, significantly impacting operational costs.

Additionally, material selection plays a vital role in valve performance. Valves must withstand the working conditions, including temperature, pressure, and the nature of the fluid. For example, a report from the International Journal of Industrial Technology highlights that using the correct materials can reduce maintenance costs by approximately 15%. Always ensure that the material compatibility aligns with the specific application to avoid premature failure.

Tips: When assessing a valve's suitability, consider conducting a pressure drop analysis to identify potential issues. Additionally, consulting manufacturer specifications can help align the valve features with your unique system needs. Lastly, seek valves with easy maintenance features to enhance overall serviceability limits and downtime.

Material Compatibility: Choosing the Right Construction for Your Environment

When selecting a three-way valve for industrial applications, material compatibility is crucial to ensure optimal performance and durability. According to a report by the Fluid Control Institute, over 30% of valve failures in industrial settings are attributed to corrosion and material degradation, underscoring the importance of choosing the right construction based on the environment in which the valve will operate. For example, materials like stainless steel and PVC are commonly used due to their resistance to corrosion and chemical exposure, which are vital in processes involving aggressive media.

In applications where high temperatures or aggressive chemicals are present, it is essential to consider materials such as PTFE or high-performance alloys. A study from the American Society of Mechanical Engineers highlights that improper material choice can lead to operational inefficiencies and increased maintenance costs, with up to 25% of operational downtime being linked to valve-related issues. Thus, understanding the chemical compatibility of different materials with the fluids being handled is not just a recommendation but a necessity for maintaining system integrity and performance.

Common Applications of Three Way Valves in Industrial Settings

Three way valves play a crucial role in various industrial applications, providing versatile solutions for controlling fluid flow. One common application is in heating, ventilation, and air conditioning (HVAC) systems, where these valves help regulate the flow of air and refrigerants. By enabling the mixing or diverting of fluids, three way valves ensure that temperature and pressure are maintained at optimal levels, promoting energy efficiency and system reliability.

Another significant use of three way valves is in chemical processing industries. Here, they manage the flow of corrosive and hazardous materials during mixing and distribution processes. By selecting the appropriate material and design, these valves can handle aggressive fluids while preventing leaks and spills, which is critical for safety and environmental compliance. Additionally, in water treatment facilities, three way valves facilitate the integration of multiple pipelines, controlling the flow of treated and untreated water effectively, ensuring proper treatment processes are followed.

How to Effectively Choose the Right Three Way Valve for Your Industrial Needs - Common Applications of Three Way Valves in Industrial Settings

| Application | Type of Three Way Valve | Operating Pressure (psi) | Temperature Range (°F) | Fluid Type |

|---|---|---|---|---|

| Water Distribution | L-Port | 150 | 32 to 180 | Water |

| Chemical Processing | T-Port | 200 | 50 to 200 | Corrosive Chemicals |

| HVAC Systems | L-Port | 300 | 40 to 150 | Air |

| Fuel Transfer | T-Port | 250 | 0 to 200 | Gasoline/Diesel |

| Pharmaceutical Manufacturing | L-Port | 100 | 60 to 180 | Washing Solutions |

Best Practices for Installation and Maintenance of Three Way Valves

When it comes to installing and maintaining three way valves, adhering to best practices is essential for ensuring optimal performance and longevity. First and foremost, proper installation begins with a careful assessment of the valve specifications and the requirements of your system. Ensure that the valve is correctly oriented according to the manufacturer's guidelines, as incorrect positioning can lead to operational inefficiencies or even catastrophic failures.

One crucial tip during installation is to use appropriate seals and fittings to prevent leaks. Inspect all components for any signs of wear or damage before installation, as this can save time and prevent issues down the line. Additionally, always tighten connections to the manufacturer’s specified torque values to avoid over-tightening, which can compromise the valve structure.

For ongoing maintenance, regular inspections are key. Check for any signs of leakage or unusual noise during operation. Implementing a routine lubrication schedule for moving parts can help reduce wear and tear, further extending the valve's lifespan. Keeping a log of maintenance activities can help track performance and identify potential issues before they escalate. By following these best practices, you not only enhance the reliability of your three way valves but also contribute to the overall efficiency of your industrial operations.

Related Posts

-

Advantages of 3 Flanged Ball Valves for Efficient Fluid Control Solutions

-

China's Leading Factory Delivers Outstanding Best 3 Way Ball Valves to Global Buyers

-

Solutions for Choosing the Best Steel Ball Valves: Key Insights from Industry Trends and Data

-

Ultimate Checklist for Selecting the Best Valve Ball Valve for Your Industrial Needs

-

5 Reasons Why the Best 3 Flanged Ball Valves Revolutionize Industrial Efficiency

-

Solutions for Optimal Pressure Management: Elevate Efficiency with the Best Pressure Valves