Complete Guide to Choosing the Right Full Port Ball Valve for Your Project

In the realm of fluid control systems, the selection of the right components is crucial for ensuring efficiency and reliability. Among the various options available, the full port ball valve stands out due to its ability to facilitate smooth flow with minimal pressure loss. According to a recent report from MarketsandMarkets, the global valve market is projected to reach USD 82.4 billion by 2027, with ball valves, particularly full port variants, accounting for a significant share due to their superior flow characteristics.

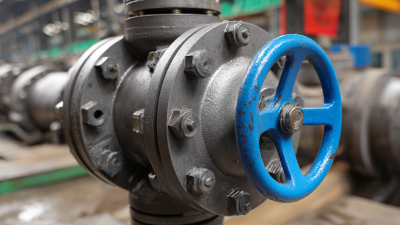

The design of full port ball valves allows for a larger inner diameter that matches the pipeline’s diameter, resulting in less turbulence and a lower chance of cavitation. This comprehensive guide will explore the different types of full port ball valves, their applications, and key considerations for choosing the right one for your project, ensuring that you make informed decisions that enhance performance and longevity in your fluid handling systems.

Understanding Full Port Ball Valves: Key Features and Benefits

When considering full port ball valves for your project, understanding their key features and benefits is crucial. Full port ball valves offer a larger diameter through the ball, which matches the pipeline’s diameter. This design allows for minimal flow resistance and reduces pressure drop, making them ideal for applications requiring maximum flow efficiency. The enhanced flow capacity also helps in maintaining the desired pressure levels within the system, ensuring optimal performance in various conditions.

When considering full port ball valves for your project, understanding their key features and benefits is crucial. Full port ball valves offer a larger diameter through the ball, which matches the pipeline’s diameter. This design allows for minimal flow resistance and reduces pressure drop, making them ideal for applications requiring maximum flow efficiency. The enhanced flow capacity also helps in maintaining the desired pressure levels within the system, ensuring optimal performance in various conditions.

Tip: Always check the valve’s pressure rating and material compatibility with your specific application. Different materials, such as brass, stainless steel, or PVC, can significantly affect the valve's performance and durability.

In addition to flow efficiency, full port ball valves are known for their ease of use and reliability. They provide tight sealing capabilities, which are essential in preventing leaks. The quarter-turn operation simplifies valve control, allowing for quick adjustments in process operations. Furthermore, their sturdy construction makes them suitable for high-pressure and high-temperature environments.

Tip: Regular maintenance checks can prolong the life of your ball valves. Ensure that the valves are operated properly and inspect for any signs of wear or damage.

Determining the Right Size and Specifications for Your Project

When selecting a full port ball valve for your project, determining the right size and specifications is crucial. According to the International Association of Plumbing and Mechanical Officials (IAPMO), proper sizing ensures optimal flow characteristics and minimizes pressure drops in piping systems. A valve that is too small can restrict flow, potentially leading to system inefficiencies, while an oversized valve may not seal properly, causing leakage and operational issues. The ASHRAE Handbook notes that flow capacity can vary significantly based on the valve's diameter, emphasizing the importance of matching the valve size with the specific requirements of your application.

In addition to size, the valve's specifications, including material composition and pressure rating, should also be carefully evaluated. A report by the American Society of Mechanical Engineers (ASME) specifies that ball valves used in high-pressure systems typically require materials that can withstand extreme conditions without deformation. For instance, stainless steel ball valves are often preferred for corrosive environments due to their durability and resistance to oxidation. Understanding the demands of your project, along with industry standards, will help ensure that you choose a full port ball valve that delivers both reliability and performance.

Material Selection: Choosing the Best Valve for Your Application

When selecting a full port ball valve for your project, the choice of material is crucial. Different applications require specific properties from the valve materials to ensure optimal performance, durability, and safety. Traditionally, materials such as brass and stainless steel have been standard, but advancements in composites and polymeric materials are reshaping the landscape. For instance, in high-pressure environments, the wear resistance of the valve material becomes paramount. Innovations in composite materials have shown promise in enhancing the durability of valves while maintaining a lightweight profile, thus improving efficiency in various applications.

Furthermore, the healthcare industry is facing unique challenges as it transitions to a circular economy. Here, the focus is not only on performance but also on sustainability. Developing valves with biodegradable or recyclable materials can significantly reduce waste from single-use devices. The emergence of polymeric materials, noted for their biocompatibility and reduced costs, presents an opportunity to align with circular economy principles while also enhancing patient outcomes in medical settings. By carefully considering the material selection, professionals can ensure that their ball valves not only meet functional requirements but also contribute positively to environmental sustainability.

Installation and Maintenance Tips for Full Port Ball Valves

When it comes to installing full port ball valves, proper techniques and attention to detail are essential for ensuring optimal performance and longevity. Before beginning the installation, ensure that the pipeline is clean and free of debris to prevent any obstructions that may affect valve operation. When positioning the valve, make sure to align it with the flow direction indicated on the valve body. This ensures that the valve operates effectively and reduces the risk of leaks.

Regular maintenance is crucial for the effective functioning of full port ball valves. One of the key tips is to periodically inspect the valve for any signs of wear or corrosion, particularly in harsh environments. Lubricating the valve’s stem and checking the seals for any damage will help preserve its functionality. Additionally, exercising the valve regularly—by fully opening and closing it—will prevent it from seizing and ensure a smoother operation over time. Always refer to the manufacturer’s guidelines for specific maintenance schedules and procedures tailored to your particular valve model.

Common Mistakes to Avoid When Selecting a Ball Valve

When selecting a full port ball valve for your project, it’s crucial to avoid common pitfalls that can impact performance and safety. One significant mistake is overlooking the valve’s pressure rating. According to the American Society of Mechanical Engineers (ASME), using a valve that doesn't meet the system's pressure requirements can lead to catastrophic failures. Ensure that the selected valve aligns with the specific pressure demands of your application, particularly in high-pressure systems where the valve could face extreme conditions.

Another common error is ignoring the compatibility of materials. A study published by the Journal of Materials Engineering and Performance highlights that improper material selection can lead to premature wear or corrosion, increasing maintenance costs and downtime. Always verify that the valve materials are appropriate for the fluids being transported. For instance, using a carbon steel valve in a corrosive environment may result in failure, while stainless steel provides enhanced durability. Taking these factors into account will not only prolong the lifespan of the valve but also ensure operational efficiency and safety.

Related Posts

-

Ultimate Checklist for Selecting the Perfect High Pressure 3 Way Ball Valve

-

Comparing Three Way Valve Designs for Optimal Efficiency in Global Supply Chains

-

5 Reasons Why the Best 3 Flanged Ball Valves Revolutionize Industrial Efficiency

-

Ultimate Checklist for Selecting the Best Valve Ball Valve for Your Industrial Needs

-

Solutions for Optimal Pressure Management: Elevate Efficiency with the Best Pressure Valves

-

China's Leading Factory Delivers Outstanding Best 3 Way Ball Valves to Global Buyers