Ultimate Checklist for Selecting the Perfect Flow Control Valve for Your Systems

In the realm of fluid dynamics, selecting the appropriate flow control valve is critical for optimizing system efficiency and ensuring operational reliability. According to a recent report by Research and Markets, the global flow control valve market is projected to reach $14.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.1%. This growth underscores the increasing significance of flow control valves in various industries, including oil and gas, water and wastewater management, and chemical processing. As systems become more complex and demand for precise flow regulation intensifies, understanding the various types of flow control valves—such as globe, ball, and butterfly valves—becomes imperative. This ultimate checklist aims to equip engineers and procurement professionals with essential insights and criteria for selecting the perfect flow control valve tailored to their specific applications, ensuring enhanced performance and cost-effectiveness.

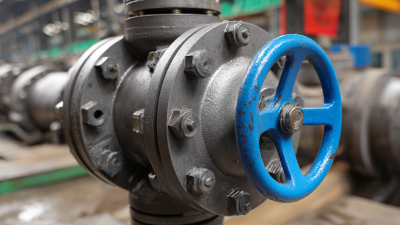

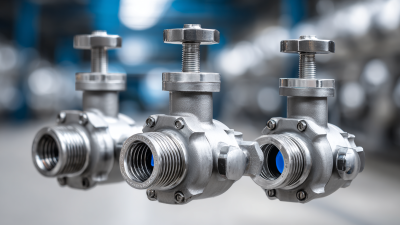

Types of Flow Control Valves: Understanding the Basics

When it comes to selecting the ideal flow control valve, understanding the various types available in the market is crucial. Flow control valves primarily fall into three categories: globe valves, ball valves, and butterfly valves. Each type serves specific functions, providing flow regulation with distinct advantages. According to the Market Research Future report, the global flow control valve market is projected to grow at a CAGR of 5.1% from 2021 to 2027, reflecting the increasing need for efficient fluid management systems across industries like oil and gas, water treatment, and HVAC.

Globe valves are known for their excellent throttling capabilities, making them suitable for applications requiring precise flow control. On the other hand, ball valves are valued for their durability and ability to provide a tight seal, making them ideal for on/off applications. Butterfly valves, characterized by their lightweight and compact design, offer quick operation in large-scale systems. A study by Valves & Actuators found that over 45% of industrial applications favor ball valves due to their ability to handle high pressures and temperatures efficiently. Understanding these distinctions is key to ensuring optimal performance and longevity in fluid control systems.

Key Performance Specifications to Consider in Valves

When selecting the perfect flow control valve for your systems, it’s crucial to consider key performance specifications that impact efficiency and reliability. Firstly, look into the valve material integrity, which must withstand various operational stresses without degradation. For applications involving aggressive media, such as hydrogen, adherence to latest standards—like the API 6D—ensures that the valve is certified for high-pressure and fugitive emissions.

Another important aspect is the flow capacity. Understanding the valve's Cv rating will help you determine its flow characteristics under different pressure conditions. This metric indicates how effectively the valve allows fluid to pass, which can significantly affect system performance. Additionally, incorporating advanced technologies, such as flow measurement and control systems, can enhance operational proficiency and provide better monitoring capabilities.

**Tips:** Always account for the operational environment when selecting valve materials to prevent premature wear. Furthermore, consider integrating IoT solutions for real-time performance analytics, which can help predict maintenance needs and optimize system efficiency.

Ultimate Checklist for Selecting the Perfect Flow Control Valve for Your Systems - Key Performance Specifications to Consider in Valves

| Specification | Description | Importance | Recommended Value |

|---|---|---|---|

| Flow Coefficient (Cv) | Measures the flow capacity of the valve | Critical for ensuring the valve can handle the required flow rate | Depends on system requirements |

| Pressure Rating | Maximum pressure the valve can withstand | Ensures safety and prevents failures in high-pressure systems | Varies by application, typically ANSI classes 150, 300, 600 |

| Temperature Range | Operating temperature limits of the valve materials | Important for material selection and system efficiency | -20°F to 450°F is common |

| Body Material | Material used for the valve body construction | Affects durability, corrosion resistance, and suitability for fluid type | Stainless steel, brass, PVC based on application |

| Actuation Type | How the valve is operated (manual or automated) | Impacts system automation and control flexibility | Electric, pneumatic, hydraulic or manual |

| Leakage Rate | Amount of flow that leaks through the closed valve | Key for applications requiring tight shut-off | Class VI or better for critical applications |

Comparative Analysis: Electric vs. Pneumatic Flow Control Valves

When it comes to flow control valves, the choice between electric and pneumatic options can significantly impact the efficiency and functionality of your systems. Electric flow control valves utilize an electric actuator to regulate flow, providing precise control and responsiveness. They are particularly well-suited for applications requiring consistent adjustments and can be easily integrated with automation systems. However, they can be more susceptible to environmental factors and may require a stable power source.

On the other hand, pneumatic flow control valves are ideal for situations where rapid action and high-speed operation are crucial. They rely on compressed air to operate, offering quick opening and closing times. This makes them advantageous in processes where rapid changes in flow are necessary. However, their performance may be influenced by fluctuations in air pressure or the availability of a compressed air supply. Moreover, maintenance can be more complex compared to their electric counterparts. Understanding these differences is crucial for selecting the right valve type that meets your operational needs and system requirements.

Ultimate Checklist for Selecting the Perfect Flow Control Valve

This chart compares the performance of Electric and Pneumatic Flow Control Valves based on various criteria including Cost, Response Time, Maintenance, Energy Efficiency, and Precision. Each criterion is rated on a scale from 1 to 10, where higher values indicate better performance.

Cost-Benefit Assessment of Different Flow Control Valve Types

When selecting the right flow control valve for your system, conducting a thorough cost-benefit assessment is crucial. According to a report by MarketsandMarkets, the flow control valve market is expected to grow from USD 6.1 billion in 2021 to USD 8.3 billion by 2026, at a CAGR of 6.4%. This growth underscores the increasing significance of investing wisely in flow control technologies. Understanding the upfront costs vs. long-term savings associated with valve types is essential. For instance, while electric actuated valves may have a higher initial price compared to manual valves, their energy efficiency and reduced maintenance requirements often lead to substantial cost savings over time.

When selecting the right flow control valve for your system, conducting a thorough cost-benefit assessment is crucial. According to a report by MarketsandMarkets, the flow control valve market is expected to grow from USD 6.1 billion in 2021 to USD 8.3 billion by 2026, at a CAGR of 6.4%. This growth underscores the increasing significance of investing wisely in flow control technologies. Understanding the upfront costs vs. long-term savings associated with valve types is essential. For instance, while electric actuated valves may have a higher initial price compared to manual valves, their energy efficiency and reduced maintenance requirements often lead to substantial cost savings over time.

Moreover, the selection of valve materials greatly influences both operational efficiency and lifecycle cost. A study by the American Society of Mechanical Engineers reveals that improperly selected materials can lead to a 30% increase in maintenance costs due to frequent repairs or replacements. Gearhead actuated valves, while slightly more expensive to install, tend to have lower total costs of ownership owing to their durability and lower failure rates across various applications. Evaluating these factors will ensure that stakeholders make informed decisions that not only satisfy immediate operational needs but also align with long-term financial objectives.

Life Cycle and Maintenance: Evaluating Valve Durability and Reliability

When selecting a flow control valve, durability and reliability are critical factors that can significantly affect a system's overall performance. According to a recent report by the Valve Manufacturers Association, more than 25% of maintenance costs in industrial operations are attributed to valve failures. This highlights the necessity for rigorous evaluation of valve materials and construction standards, especially in harsh environments. For instance, valves made from high-quality stainless steel or specific alloys can withstand corrosive substances, ultimately extending their life cycle and reducing maintenance requirements.

Furthermore, predictive maintenance has emerged as a crucial strategy in evaluating valve reliability. The use of advanced monitoring technologies, as revealed in a study by the American Society of Mechanical Engineers, can improve failure predictions by up to 70%. By integrating real-time data analytics into the valve management process, operators can identify issues before they escalate, minimizing downtime and repair costs. Investing in flow control valves that offer durability and advanced monitoring capabilities ultimately leads to a more efficient and cost-effective operation.

Related Posts

-

Ultimate Checklist for Selecting the Best Valve Ball Valve for Your Industrial Needs

-

5 Reasons Why the Best 3 Flanged Ball Valves Revolutionize Industrial Efficiency

-

Global Leaders Choice for Best Three Way Ball Valves Quality Manufacturing from China

-

Solutions for Optimal Pressure Management: Elevate Efficiency with the Best Pressure Valves

-

China's Leading Factory Delivers Outstanding Best 3 Way Ball Valves to Global Buyers

-

Ultimate Guide to Sourcing the Best Flow Valve Suppliers for Quality Assurance