Advantages of 3 Flanged Ball Valves for Efficient Fluid Control Solutions

In the realm of fluid control solutions, the demand for efficient and reliable systems has never been greater. According to a recent report by MarketsandMarkets, the global valve market is projected to reach $82 billion by 2027, driven by the need for better management of fluid processes across various industries such as oil and gas, water treatment, and chemical manufacturing. Among the myriad of valve options available, the 3 flanged ball valve stands out due to its unique advantages in providing tight sealing, minimal pressure drop, and durability under high-pressure conditions. This type of valve not only facilitates precise flow regulation but also enhances system longevity, thereby contributing to overall operational efficiency. As industries continue to seek ways to optimize their fluid management processes, understanding the benefits of 3 flanged ball valves becomes increasingly crucial for achieving superior control and performance.

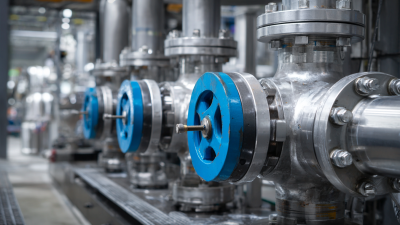

Key Benefits of Three Flanged Ball Valves in Fluid Control Systems

Three flanged ball valves are increasingly recognized for their vital role in enhancing fluid control systems across various industries. One of the key benefits of these valves is their ability to provide a tight seal, which significantly reduces the chances of leaks. This feature is particularly important in critical applications where fluid loss can lead to safety hazards and financial losses. Moreover, the streamlined design of three flanged ball valves ensures minimal pressure drop and improved flow efficiency, making them ideal for high-performance fluid control solutions.

Another significant advantage of three flanged ball valves is their ease of installation and maintenance. With flanged connections, these valves can be easily integrated into existing systems without extensive modifications. This ease contributes to lower operational costs and reduced downtime, which are crucial factors for businesses competing in today's fast-paced markets. As reported, the control valve market is projected to grow from $10.42 billion in 2025 to $13.30 billion by 2030, highlighting the increasing demand for efficient and reliable fluid control mechanisms, including three flanged ball valves. Their indispensable role in this growth trajectory illustrates the value they bring to fluid control systems, making them a preferred choice for engineers and plant managers alike.

Comparative Analysis: Three Flanged Ball Valves vs. Traditional Valves

In recent years, the demand for efficient fluid control solutions has propelled the adoption of innovative valve technologies, particularly

flanged ball valves. A comparative analysis of three flanged ball valves versus traditional valves reveals significant advantages in performance.

Studies indicate that these modern valves can achieve a flow coefficient (Cv) up to 30% higher than their conventional counterparts, resulting in reduced energy consumption and enhanced system efficiency.

The ability to maintain tight sealing under varying pressure conditions further establishes their superiority, allowing for greater operational reliability.

Recent advancements in valve design, particularly the integration of

Finite Element Modeling (FEM) and

Computational Fluid Dynamics (CFD), have optimized traditional designs such as the butterfly valve.

Research has demonstrated that optimizing the weight of the valve disc not only improves flow characteristics but also reduces the overall strain on piping systems. This kind of innovation underscores the importance of evolving past

traditional valve designs, as the differentiated performance of three flanged ball valves can lead to significant operational savings and increased longevity of industrial applications.

Such developments emphasize the need for industries to reassess their fluid control solutions to remain competitive in an increasingly efficient market.

Enhanced Sealing Performance: How Three Flanged Ball Valves Excel

Three flanged ball valves are increasingly favored in industrial applications due to their enhanced sealing performance, which is crucial for efficient fluid control. These valves utilize three flanges that provide a secure connection, reducing the risk of leakage compared to traditional designs. According to the Fluid Control Industry Report 2022, valves with advanced sealing mechanisms can lower leakage rates by up to 50%, which not only improves operational efficiency but also minimizes environmental risks associated with fluid spills.

Moreover, the design of three flanged ball valves allows for better sealing under varying pressure conditions. The American Society of Mechanical Engineers (ASME) indicates that robust sealing solutions are essential in high-pressure systems, where even minor leaks can lead to significant losses both in terms of resources and safety. By incorporating materials like PTFE or PEEK in the sealing components, these valves achieve exceptional performance, maintaining integrity across a broad temperature range. This advancement not only boosts reliability but also extends the lifespan of the equipment, reducing maintenance needs and costs in the long run.

Advantages of 3 Flanged Ball Valves for Efficient Fluid Control Solutions

Versatility in Applications: When to Choose Three Flanged Ball Valves

Three flanged ball valves are gaining traction in various sectors due to their versatility and reliability in controlling fluid flow. These valves are particularly suited for applications that demand high performance and adaptability, such as in water treatment, chemical processing, and oil and gas industries. Their robust construction and three-flange design ensure a secure fit, minimizing the risk of leaks and failures.

When considering three flanged ball valves for your project, think about the specific requirements of your application. Tips include assessing the type of fluid being controlled, as some materials are more compatible with specific media. Additionally, evaluate the pressure and temperature conditions, as these factors will influence valve performance and longevity. Choosing the right size is also crucial; an appropriately sized valve ensures efficient fluid control and prevents unnecessary wear and tear.

When considering three flanged ball valves for your project, think about the specific requirements of your application. Tips include assessing the type of fluid being controlled, as some materials are more compatible with specific media. Additionally, evaluate the pressure and temperature conditions, as these factors will influence valve performance and longevity. Choosing the right size is also crucial; an appropriately sized valve ensures efficient fluid control and prevents unnecessary wear and tear.

Furthermore, consider the maintenance needs of the valves. Regular inspections and timely servicing can enhance their operational lifespan and reliability. In applications where downtime is costly, investing in high-quality three flanged ball valves can provide peace of mind and assure seamless operations.

Cost-Effectiveness of Three Flanged Ball Valves: A Comparison with Alternatives

When considering fluid control solutions, cost-effectiveness is often a determining factor in the selection of equipment. Three flanged ball valves stand out as a competitive choice compared to their alternatives, such as gate or globe valves. The simplicity in design of three flanged ball valves facilitates efficient manufacturing processes, reducing both production and maintenance costs. These valves typically require less frequent repairs due to their robust construction, further enhancing their economic appeal over time.

In addition to initial savings, the long-term operational efficiency of three flanged ball valves contributes significantly to their cost-effectiveness. Their low pressure drop ensures minimal energy loss in fluid transfer, making them an ideal choice for systems where efficiency and performance are critical. Furthermore, their compact design and user-friendly installation can save on labor costs, further tipping the scale in favor of three flanged ball valves when making a budget-conscious decision for fluid control solutions.

Related Posts

-

Comparing Three Way Valve Designs for Optimal Efficiency in Global Supply Chains

-

Solutions for Sourcing the Best Ball Valve Balls: A Global Procurement Guide

-

Ultimate Guide to Sourcing the Best Flow Valve Suppliers for Quality Assurance

-

Ultimate Checklist for Selecting the Perfect High Pressure 3 Way Ball Valve

-

Understanding the Significance of the Best High Pressure Ball Valve in Industrial Applications

-

Ultimate Checklist for Selecting the Perfect Flow Control Valve for Your Systems